DeRun FS Series Waterproof Connector For IP65 Silicone Tube Waterproof LED Strip

Product Name: DeRun FS Series Waterproof Connector for IP65 Silicone Tube Waterproof LED Strip

Features

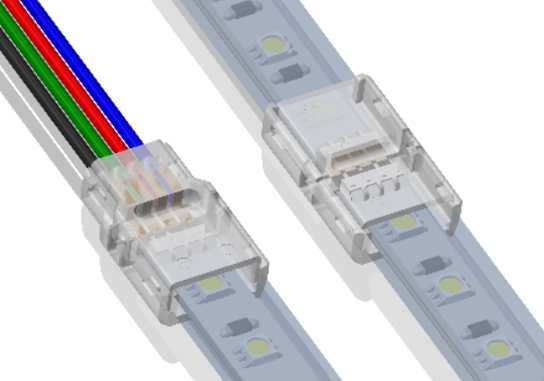

New FS series connector: the new design brings a safe, fast, and convenient installation with led strip light. It not only achieves a rapid free welding connection but no length requirements to the layout of the wireline.

DeRun FS series connector improved the flexibility and convenience of the application site. It is easy to connect to the tin-free wire and does not need to strip the wire skin.

The conductor is not exposed, so it’s very safe. It makes the cut wire’s direct fast connection come true.FS series connectors have clear housing, ensuring led emitting chip good light transmission.

The innovative internal connection structure brings a better bite force between led strip light and connectors, more stability.

Specification

Housing: Polycarbonate

Contact chip: Environmental protection hardware material high precision copper

Contact chip surface treatment: Environmental protection and anti-corrosion treatment

Rated voltage: 0-36V

Rated current: 5A

Working temperature: -20 ℃~50 ℃

Temperature resistance: housing 105°C

Flame retardant grade: UL-94-V0

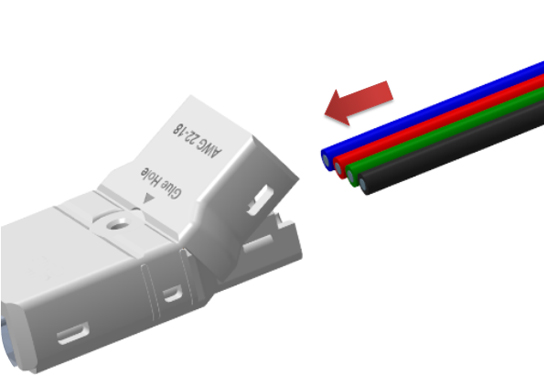

Conductor cross-section: 0.35 mm²~0.75 mm ( AWG22~AWG18)

Wire diameter requirement(including insulation): Φ1.5 mm~Φ 2.1mm

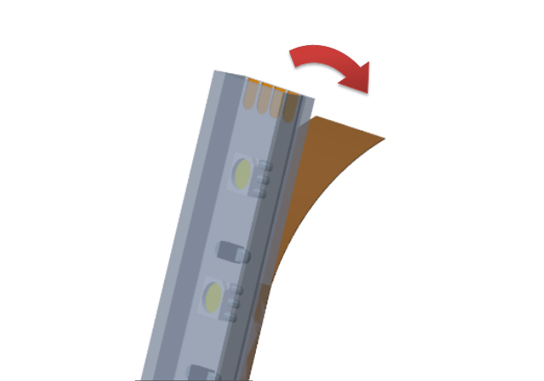

Led strip requirement: Waterproof IP65(square shape), Single color & RGB, Led quantity 30-120pcs/m, led strip size 12.5mmX4mm

Led strip PCB requirement: Plating plate (not suitable for wire plate), thickness 0.25mm~0.35mm

Glue feature:

P/N: SC-1512

Description: Paste with transparent or translucent adhesive Capacity: 10 ml/pcs

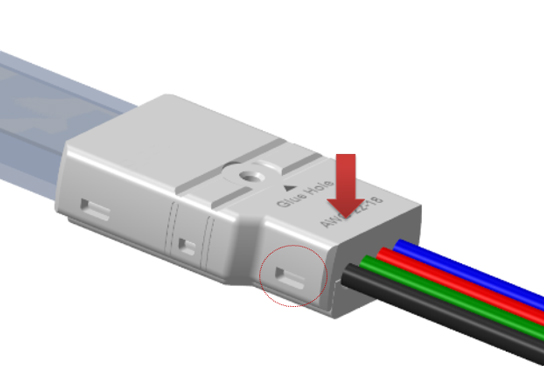

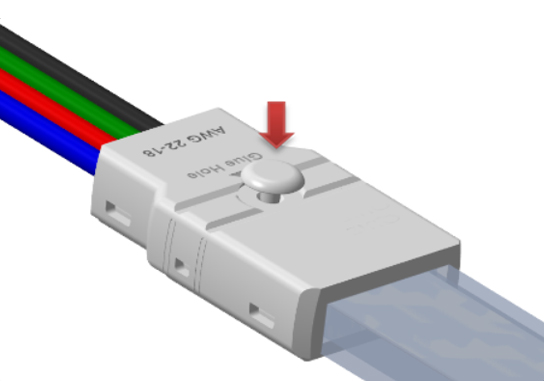

Tip: DeRun FS Series waterproof connectors do not have their own waterproof conditions. It must be used with special glue(2ml of half flow transparent waterproof glue) to achieve a waterproof effect if installed in an outdoor or humid environment.

For connector waterproof operation, please refer to the following:

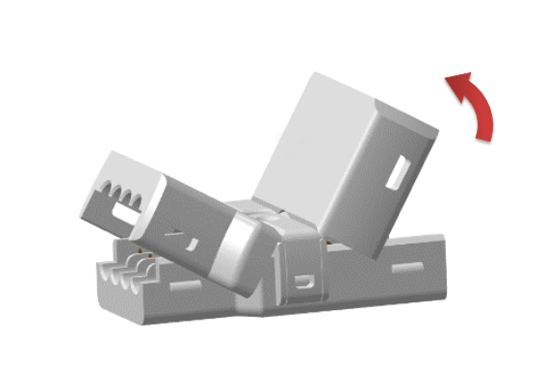

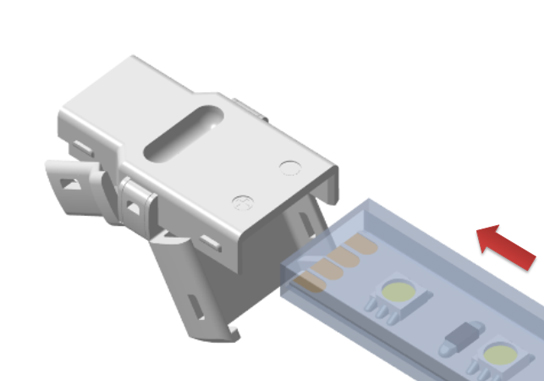

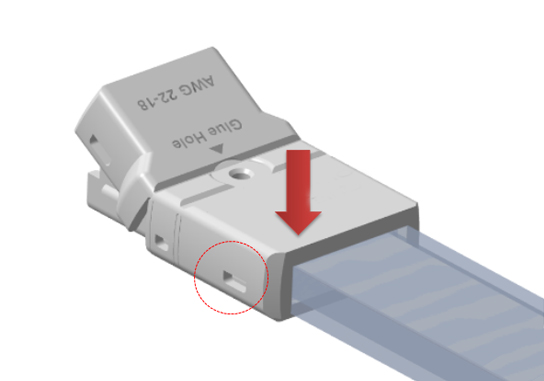

Connection

Some possible reasons if the electricity does not work:

1. Please check whether the wire is standard.

2. Is the polarity of the wire and strip wrong?

3. Is the led strip PCB thickness matching?

4. Is the strip soldering pad in contact with the metal contact sheet completely?

5. Is the led strip light in good condition?